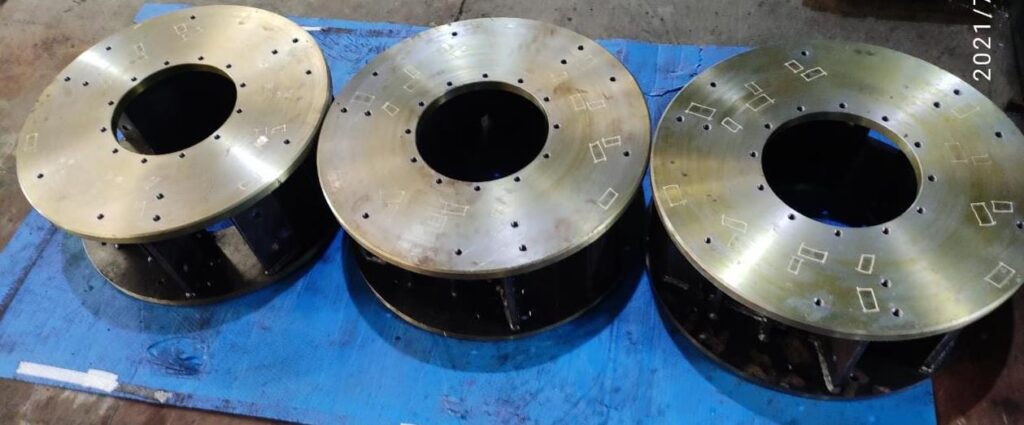

Fabricated & machining Assemblies for stone crusher equipment

Fabricated & Machining Assemblies For Stone Crusher Equipment

The assembly of stone crusher equipment at Dynamic Industries involves multiple steps and tasks to ensure the machinery functions properly. Skilled technicians carefully install components, test the equipment, and make final adjustments for efficiency and safety.

Attention to detail and expertise are required during the assembly process to meet quality standards and prepare the equipment for various applications.

Fabricated assemblies for stone crusher equipment: It refers to custom-built components essential for the functioning of stone crushing machinery. These assemblies are meticulously crafted to ensure durability, efficiency, and seamless integration within the crusher system. Designed to withstand rigorous conditions, they play a crucial role in the crushing process, contributing to the overall reliability and performance of the equipment.

Machining assemblies for stone crusher equipment: Precision machining assemblies tailored for stone crusher equipment, ensuring optimal performance, durability, and efficiency. Our expertly crafted components are meticulously engineered to meet the rigorous demands of the stone crushing industry, providing reliable operation and extended service life.”

Fabrication and machining assemblies for stone crusher equipment involve the creation and assembly of various components that constitute the equipment. These assemblies typically include parts such as the frame, housing, rotor, crushing chamber, bearings, screens, and other essential elements. The fabrication and machining processes ensure that these components are precisely manufactured to meet the specifications required for the efficient functioning of the stone crusher equipment.

Working Principles:

The working principle of a stone crusher equipment involves the use of mechanical force to break larger stones into smaller pieces. This is typically achieved through the application of compressive forces generated by a rotating rotor or by the impact of the stones against each other within a crushing chamber. The key components such as the rotor and crushing chamber are designed to facilitate the crushing process effectively.

Understanding the differences between machining and fabrication is necessary before you understand how they function together. The phrases “fabrication” and “machining” are used in industry to describe the steps involved in creating a product. While fabrication assembles several standardized elements to make a final product, machining uses large-scale industrial procedures to transform raw materials into finished items. In basic terms, fabrication is the process of putting together already created parts to create a product, whereas machining is creating a thing from the ground up.

Primary Crushing: Large stones are fed into the crushing chamber, where they are subjected to the action of the rotor or impactors. The high-speed rotation of the rotor combined with the impact force breaks down the stones into smaller pieces.

Secondary Crushing: Smaller stones or particles resulting from primary crushing may undergo further crushing in secondary or tertiary crushing stages, where finer crushing is required.

Application:

Stone crusher equipment finds applications in various industries, including:

- Mining: Crushing of ores and minerals to extract valuable metals or minerals.

- Construction: Breaking down large rocks into smaller sizes for use in construction projects such as road building, concrete production, and landscaping.

- Demolition: Crushing of concrete and demolition debris for recycling purposes.

- Aggregate Production: Crushing of natural stone or recycled materials to produce aggregates for use in concrete, asphalt, and other construction applications.

Advantages:

- Efficient Crushing: Fabricated and machined assemblies ensure that the stone crusher equipment operates efficiently, delivering high throughput with minimal downtime.

- Customization: Fabrication allows for the customization of equipment to meet specific application requirements, ensuring optimal performance in various operating

conditions.

- Durability: Well-fabricated components and assemblies are designed to withstand the harsh operating conditions typically encountered in mining and construction environments, resulting in long-term durability and reliability.

- Maintenance: Properly fabricated equipment is designed for ease of maintenance, allowing for quick and convenient servicing of components to minimize downtime and maximize productivity.

- Versatility: Stone crusher equipment can be adapted for use in different applications and environments, making it a versatile solution for various industries.

Fabrication and machining assemblies manufacture in Pune and across India by Dynamic Industries for stone crusher equipment demonstrate precision engineering and robust construction, ensuring optimal performance and durability. We deliver high-quality solutions tailored to the demands of the stone crushing industry, solidifying their reputation as a reliable provider of cutting-edge equipment.

For inquiries regarding our Fabricated & machining Assemblies for stone crusher equipment, please feel free to contact us via email at [email protected] or by phone at +91 9370816363. We look forward to assisting you with any questions or requirements you may have.